Maximum energy efficiency

for corrugated board production

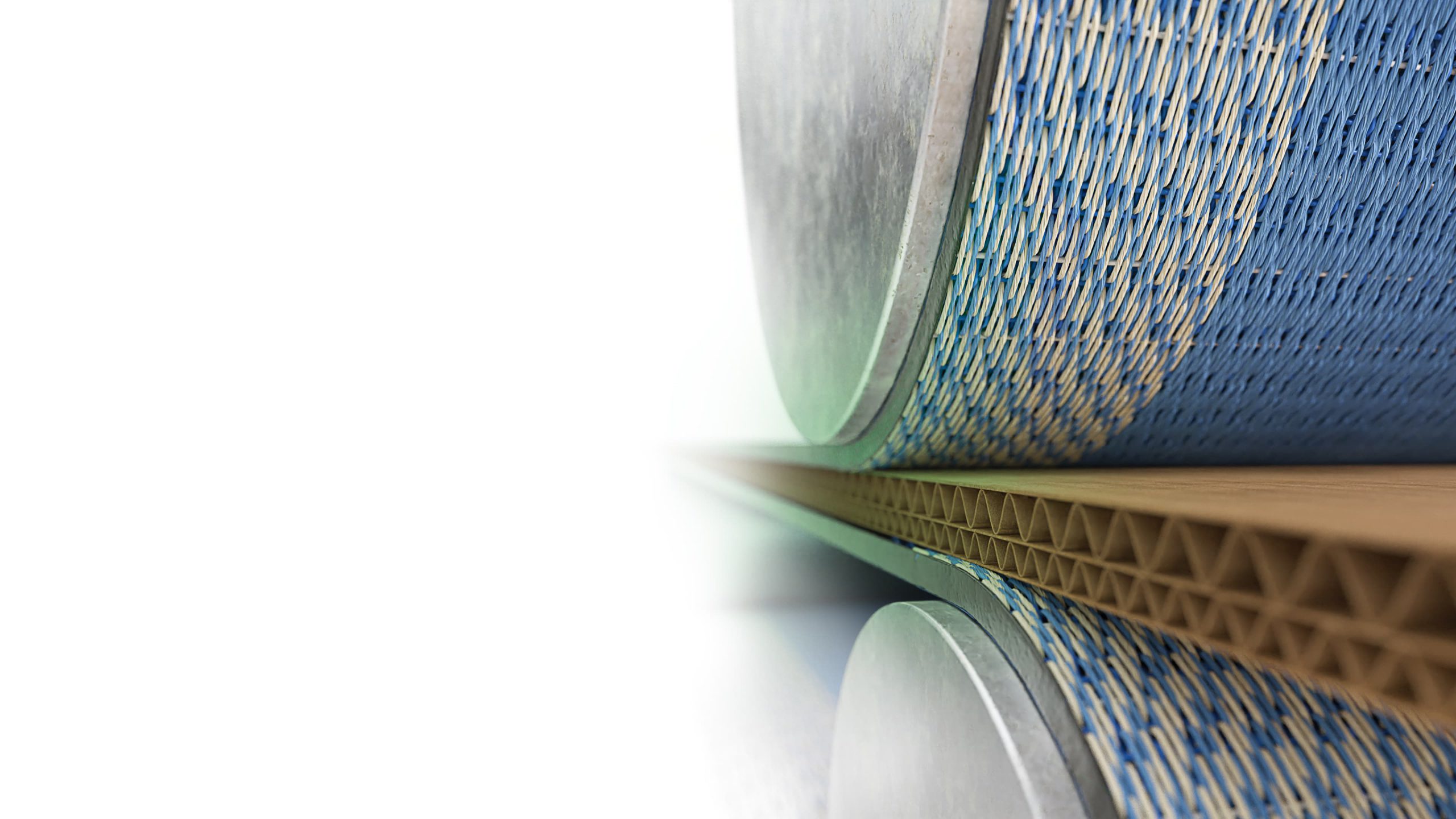

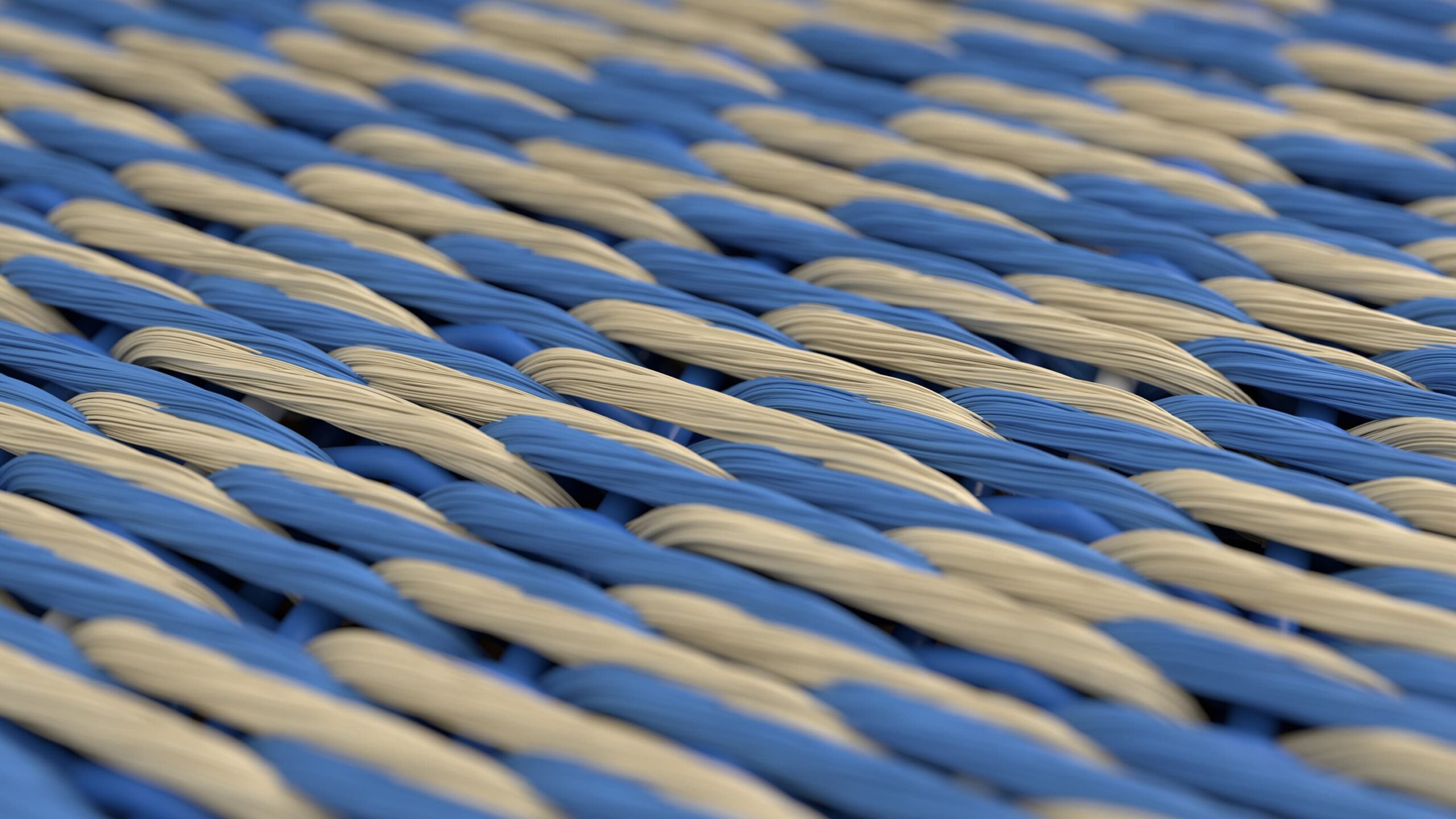

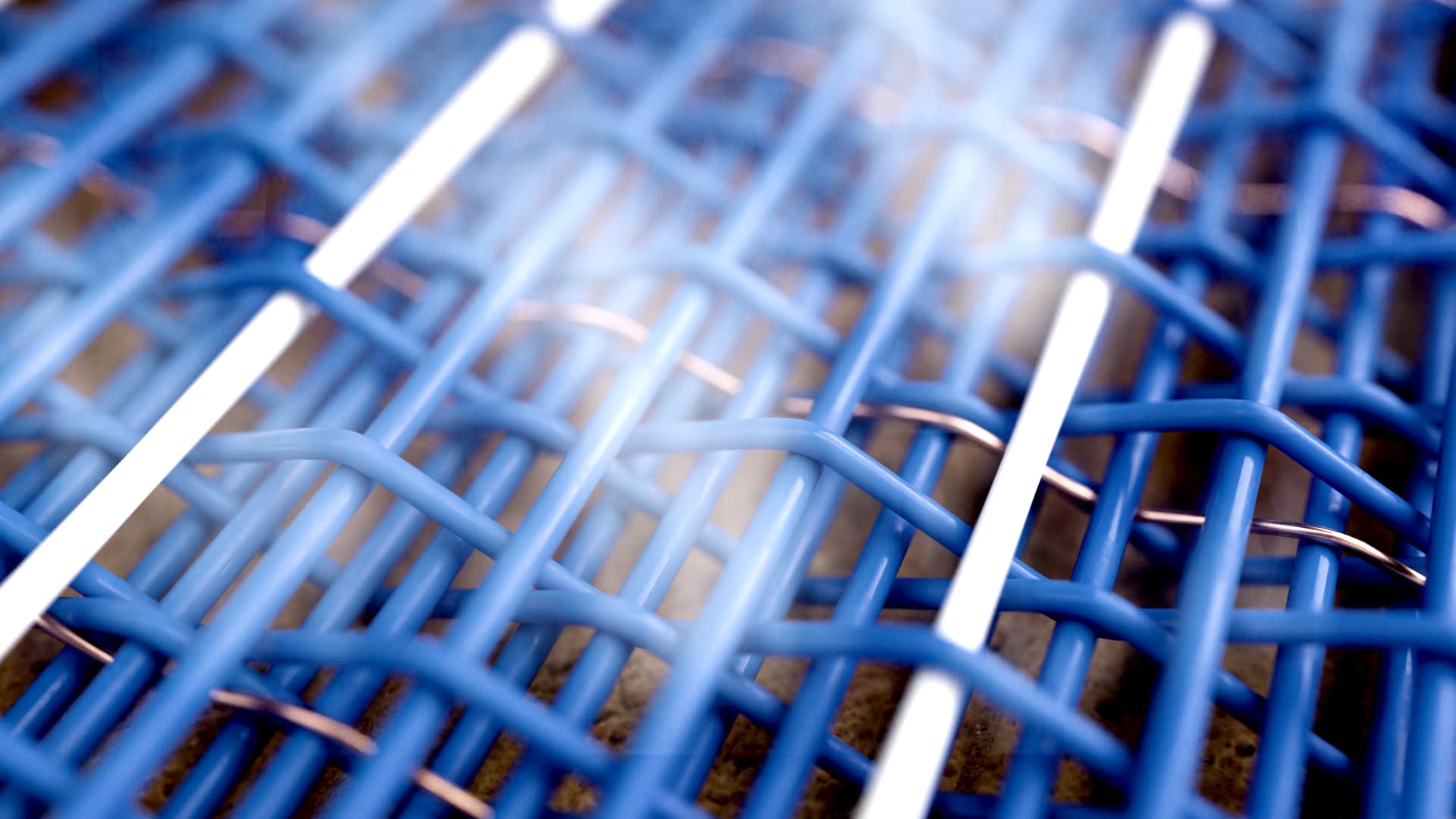

The innovative new BLUEBACKER process belt for corrugated board applications employs a mesh technology with resistant and open mesh design. It helps secure more efficiency during the corrugated board production and is used as both as a top and lower belt.

corrugator Belt

BLUEBACKER is produced from a unique, multilayer mesh for more efficiency for corrugated board production.

Constant electrostatic discharge – this prevents the corrugated board from sticking.

Ensures reliable grip of the corrugated board. Abrasion problems are prevented, what results in a long service life.

Any risk of belt elongation is prevented throughout the entire service life. A high degree of cross stability is guaranteed.

The benefits at a glance

Developed and produced in Germany.

On unmatched quality standard since 1925.

Sustainability

Thanks to high air permeability of the heating belt faster and uniform evaporation of the corrugated board.

Up to

0

lower energy

consumption*

Up to

0

Increase in

production speed*

Up to

0

Less driving

energy*

*Depending on the specific conditions and installations at the place of use

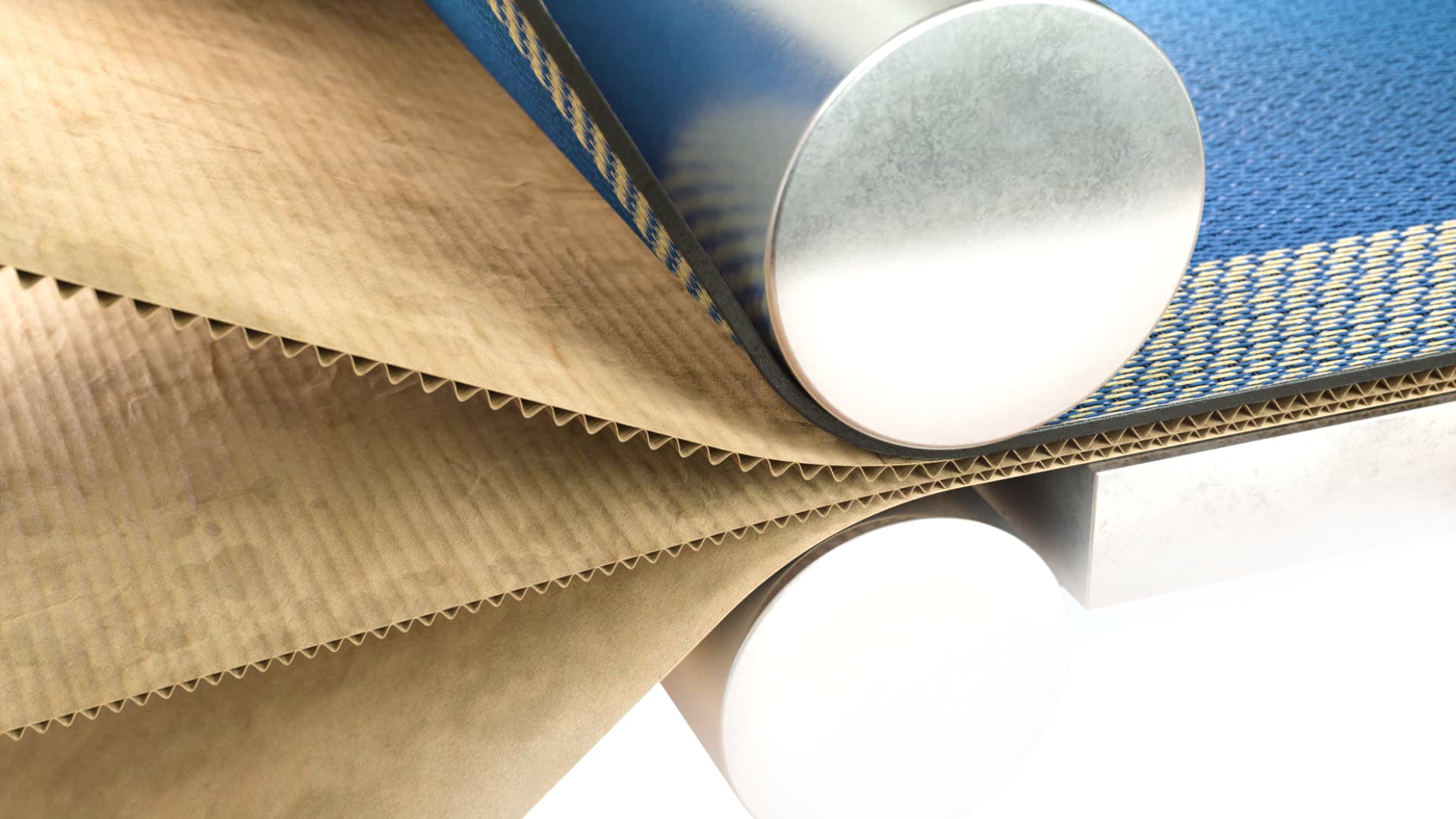

lower belt

The lower belt comes with CONDUCTO® technology as standard that prevents the corrugated board from sticking. Any risk of fire can therefore be minimized.

uncoated

The uncoated lower belt is universally suited to all corrugated board production systems. It can also be used at all production speeds.

coated

The special, tried-and-tested silicone coating significantly increases paper grip. The belt is therefore ideal for use with heavy grammatures and smooth surface papers.

Expertise

GKD is the worldwide technological leader for solutions produced from metallic, hybrid, and synthetic mesh and spirals. Innovative belts from GKD increase the efficiency of industrial processes, whether filtering, pressing, dewatering, separating, stamping, drying, cooling, freezing, or heat treatment.

Products from GKD are manufactured to the highest standards. Thanks to ISO certifications, you can rely on certified quality worldwide. The electrostatic discharge of our corrugator belt is also ATEX-certified.

Contact

GKD – Gebr. Kufferath AG

Metallweberstr. 46

52353 Düren

Germany

T +49 2421 803 0

bluebacker@gkd-group.com

GKD-USA, INC.

825 Chesapeake Drive

Cambridge, MD 21613

USA

T +1 410 221 0542

sales@gkdusa.com